Mechanical Engineering

Mechanical engineers are professionals working in industry or as consultants who specialize in designing, analyzing, and improving mechanical systems and devices. They apply their expertise in physics, mathematics, material science, and computer applications to create innovative solutions for a wide range of industries, including automotive, aerospace, energy, infrastructure, and general product manufacturing. Mechanical engineers are involved in every stage of a product's lifecycle, from conceptualization and design to testing, production, and maintenance. They utilize computer-aided design (CAD) software and simulation tools to develop and optimize designs, ensuring functionality, efficiency, and reliability. Additionally, mechanical engineers collaborate with interdisciplinary teams, addressing challenges related to mechanics, thermodynamics, fluid dynamics, and structural analysis, with the goal of creating safer, more sustainable, and technologically advanced products and systems.

AVERAGE BSME STARTING SALARY

OF GRAD STUDENTS ARE PURSUING PhD

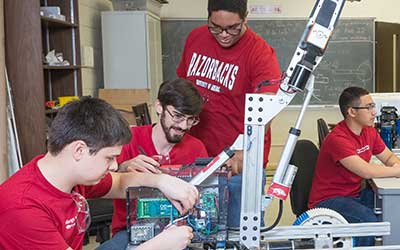

HANDS-ON DESIGN PROJECTS BEGINNING SOPHOMORE YEAR

BSME + AEROSPACE CONCENTRATION AVAILABLE

PLACEMENT

RATE

Quick Links

News

Get your current news stories!

Senior Design Projects

Learn about current senior design projects.

Graduate Assistantships

Learn more about our teaching and research assistantships.

Forms & Resources

Be prepared, find student, travel and other forms.